STM32 Closed Loop 42 Stepper Motor kit for 3D Printing Compatible Mechaduino

Motor parameters:

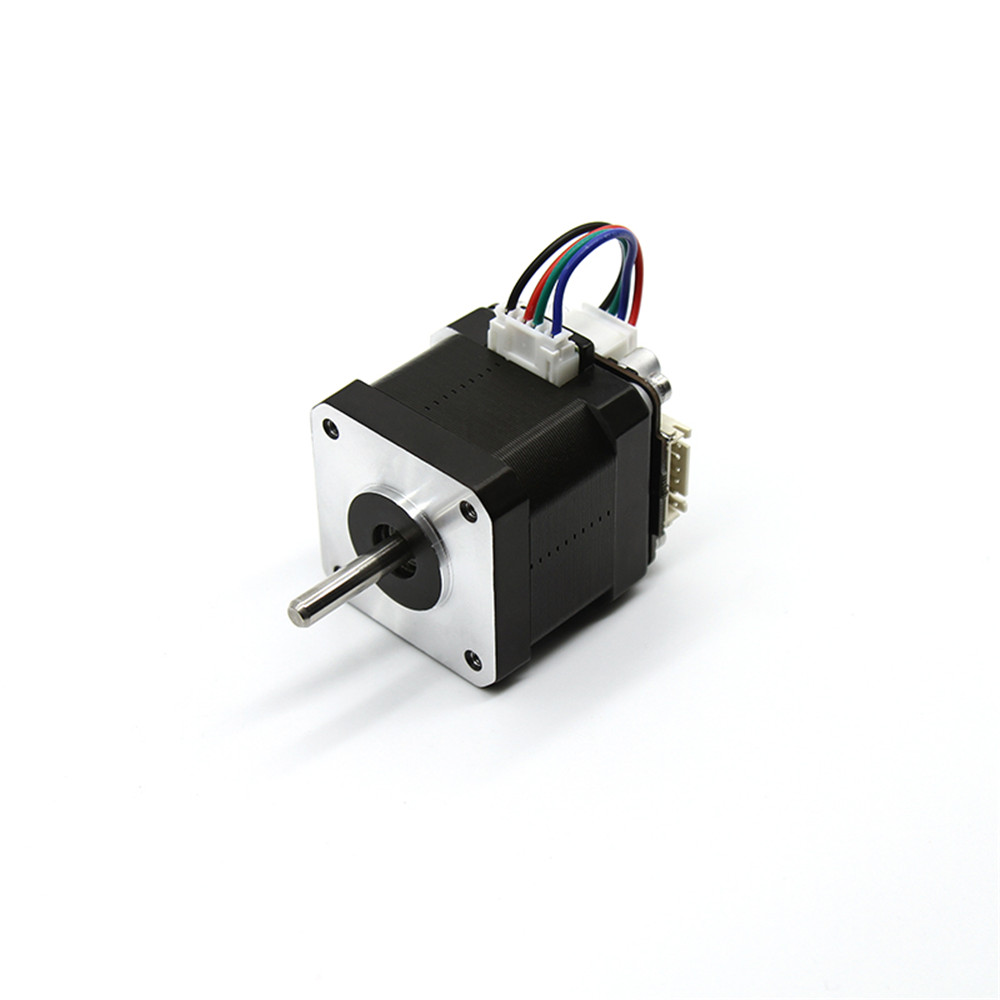

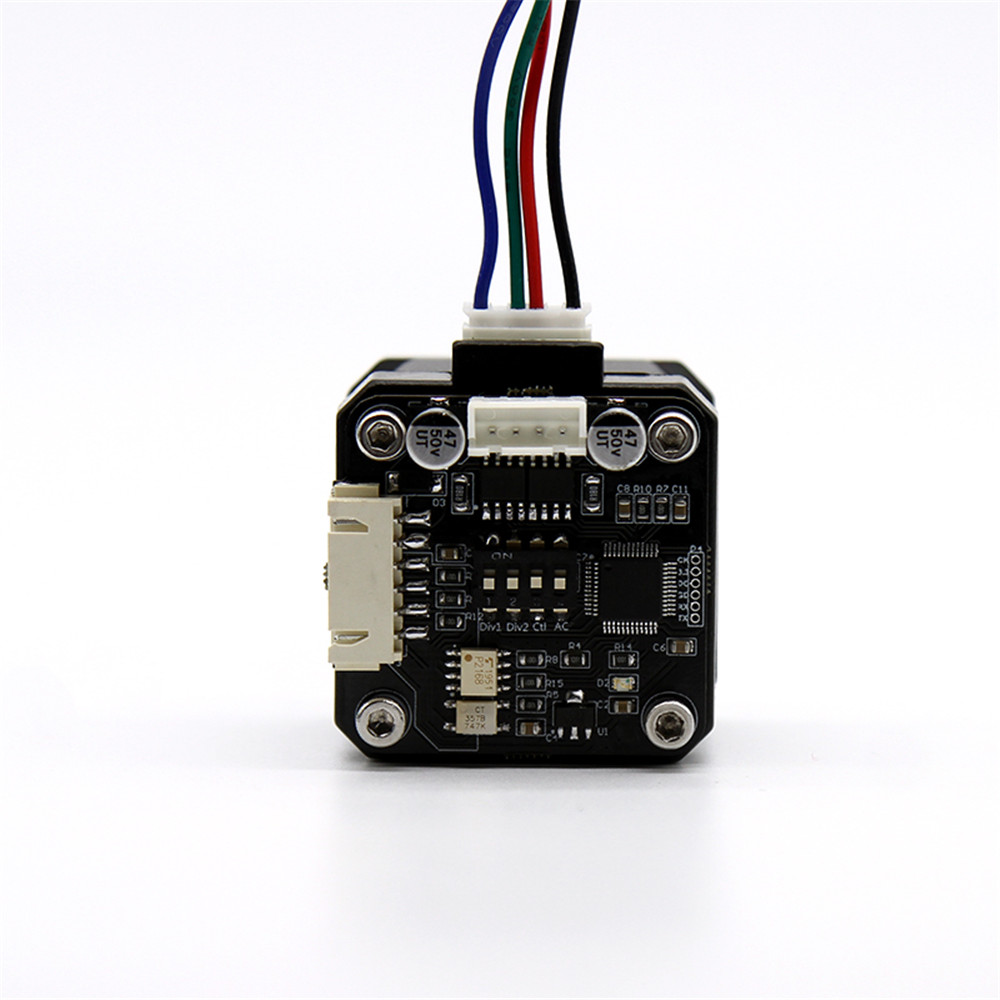

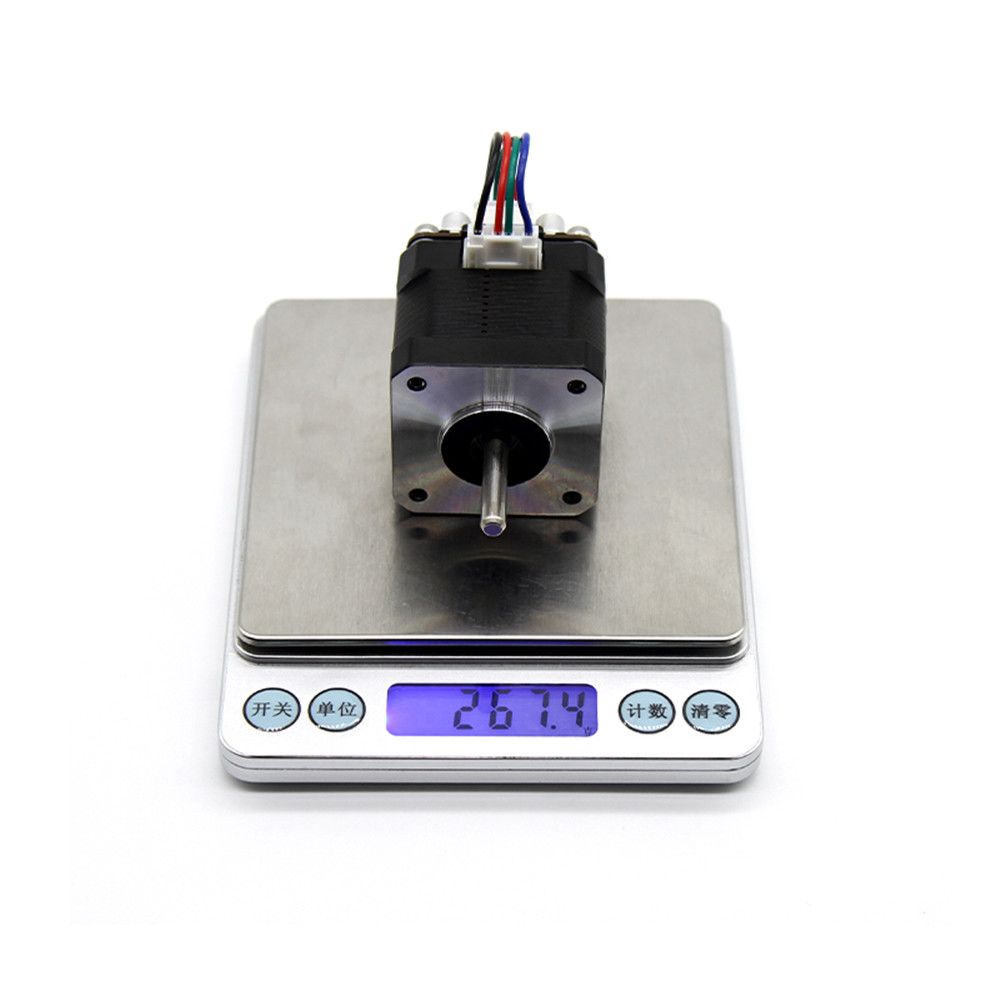

Product Name: 42 two-phase stepper motor

Material:Metal

Color:As the picture shown

Product Size:Length is 75mm max diameter is 55mm

Package Box Size:135*80*90mm

Product Weight:About 267.4g

Packaging Weight:Approx.334g

Model number :17HS4401

Step angle : 1.8 deg

Max no-load starting frequency : >= 1400 PPS

Rated voltage 3.6V

Max no-load operating frequency : >= 4000 PPS

Rated current : 1.5A / phase

Phase inductance :3.7 x (1 + 20%) mH

Holding torque : >=420 mN.m

Phase resistance : 2.4 x (1 + 15%) O / phase

Positioning torque : 15 mN.m REF

Electric strength : AC600V / 1mA / 1S

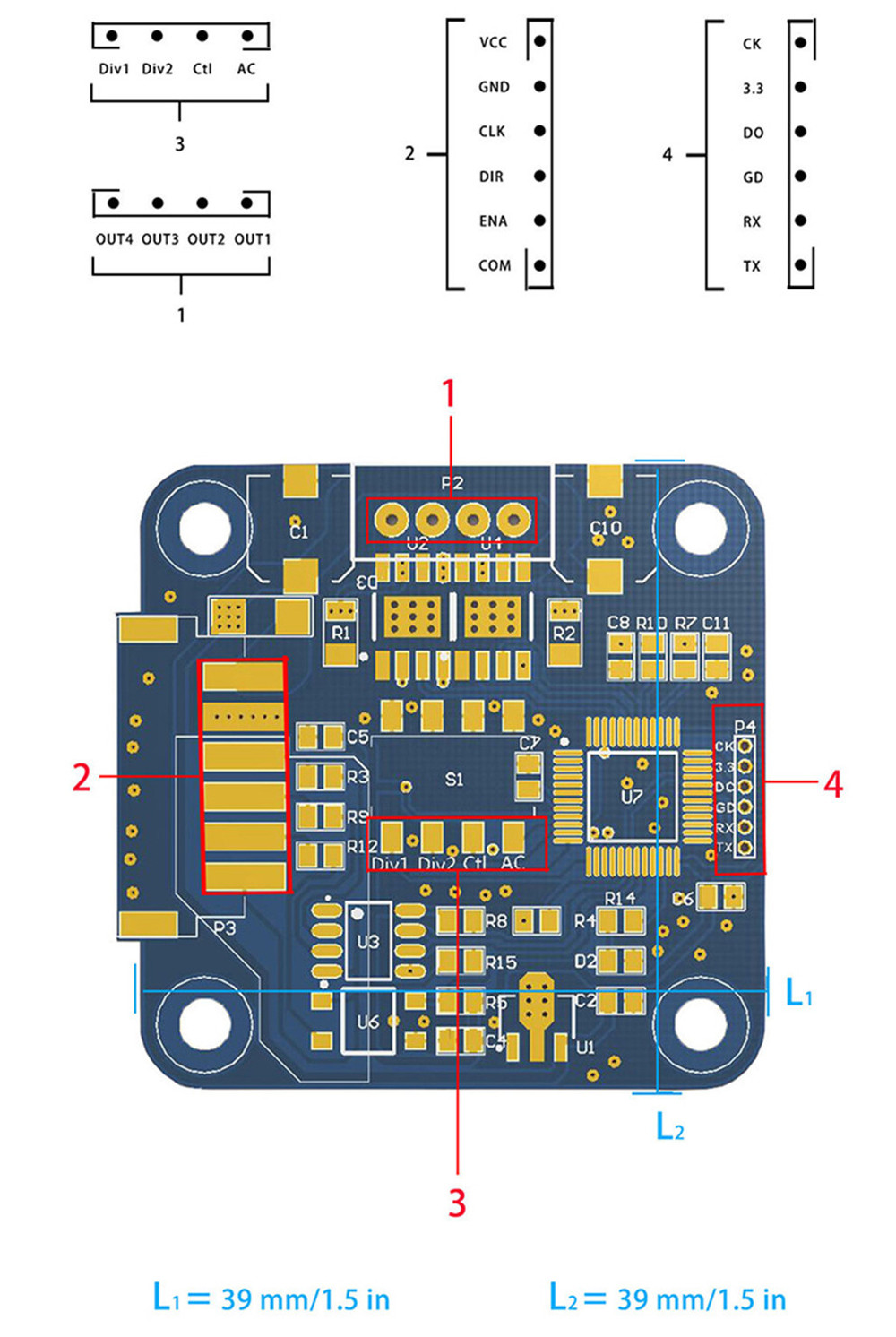

Wiring Instructions:

1. VCC : Connect 12-30V power supply ( Refer to the working voltage of the motor general 24V )

2. GND: Ground wire

3. CLK : Control signal (Connected to pulse input )

4. DIR: Direction control signal ( Floating forward ground reverse )

5. ENA: Connect to enable signal ( Default enable grounding stops working )

6. P2: Connect one phase to the motor on each side ( Refer to the motor parameter description the motor is divided into two phases AB pins 1 and 2 are connected to one phase and pins 3 and 4 are connected to the other phase. )

DIP switch {ON (1) / OFF (0)}:

1.Div1 Div2 control pulse frequency division

(1) 00: 4 subdivision

(2) 10: 8 subdivision

(3) 01:16 subdivision

(4) 11:32 subdivision

2.Ctl setting control mode open-loop / closed-loop

(1) 0 : Open-loop mode

(2) 1 : Closed-loop mode

3.AC setting calibration

Turn the AC to position 1 and turn on the power. The LED blinks 3 times to start automatic calibration. The motor shaft rotates counterclockwise for one cycle and then clockwise for one cycle. The system automatic calibration complete and the LED continues to flash. The AC dial returns to position 0 and then restart power.

Application examples:

1.3D printing with fine closed-loop positioning

2.Optical aiming (Laser telescope camera gimbal etc.)

3.Speed loop record player

4.Force feedback / impedance control robot

5.Force feedback of game controller

6.Adjustable mechanical impedance: virtual spring damper etc.

7. Electric transmission device between two axes such as CNC machine tools

8.Gravity elimination (eg: offset gravity torque on the robot arm etc.)

9. Load detection and feature description (Used as a balance etc.)

10. Paper towel / TP distributor

11.Variable load (Brake generator etc.)

12.Valve control (Automated garden hose etc.)

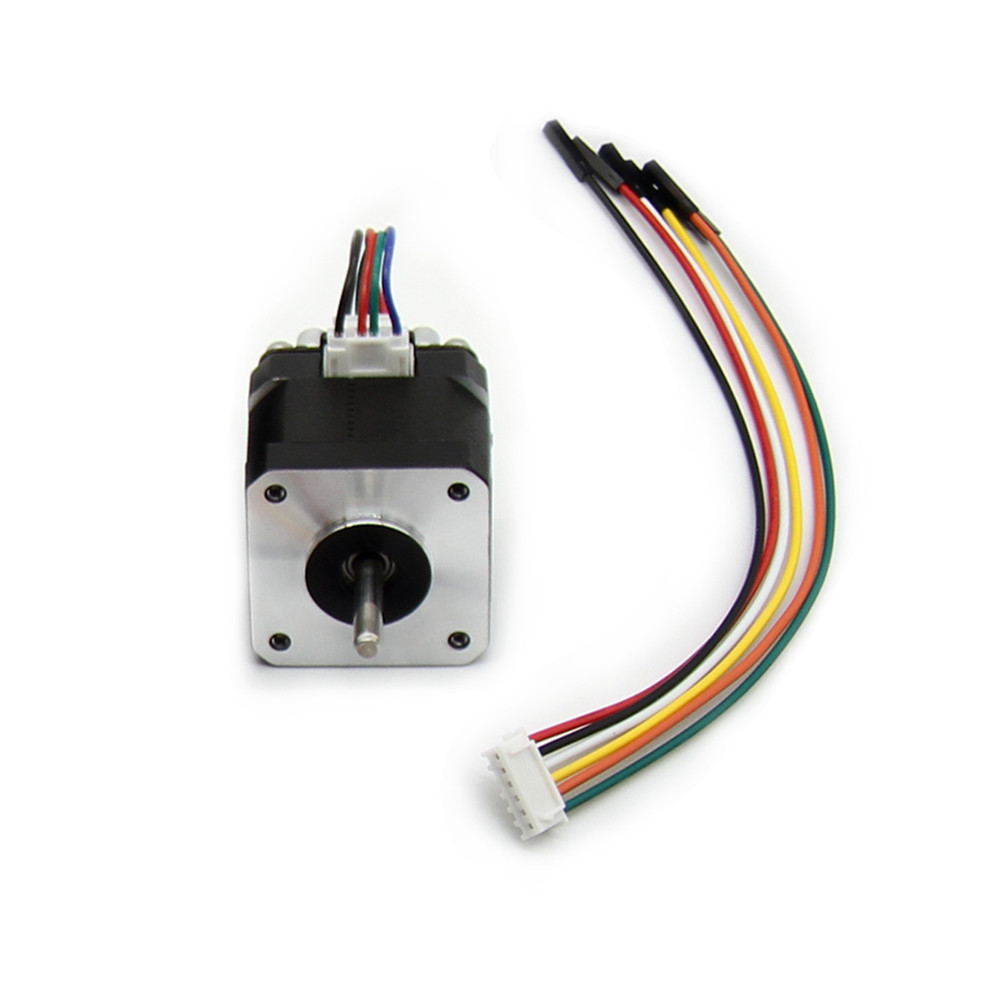

Package included :

1 x Motor Drive Board

1 x Motor

1 x Motor Line

1 x Dedicated Radial Magnet

1 x Dedicated Srew Bag

1 x Instruction Manual